Human experience is deeply rooted in food and in the cycle of human activity that includes food production, distribution, manufacturing, shopping, and finally, eating. This cycle shapes our daily lives at work and at rest, in politics and in play, in our bodies and in our imaginations.

For many of us, these food experiences are professional as well as personal. Food scientists and farmers alike experiment with ways to produce more, and hopefully higher quality, food. Entrepreneurs and innovators engineer processes to manufacture a cornucopia of flavors from a few staple ingredients. They design distribution systems that bring diversity to our markets, kitchens, and tables. They create shopping experiences that speak to our personal desires and foretell pleasures to come. And as mealtime approaches, they help busy humans, including themselves, make those pleasures both convenient and real in ways that range from healthy to hedonistic.

Over the last few decades, our planet’s complex food system has thus developed several core strategies for optimizing this cycle of food experiences. Production aims for intensification. Distribution requires efficiency. Manufacturing is at its best when it can be standardized. Shopping centralizes food in a common marketplace. And when it comes to eating, convenience and affordability still dominate diners’ considerations.

These strategies have been well honed by generations of people engaged in the experience of food. But today, these strategies are encountering their limits. Technological innovations are poised to take us beyond those limits, to transform the way we experience food in all our encounters with it. Over the next decade, we will re-experience food as we look to these technologies—not just to help us breach these limits, not only produce the food we need, but also to fulfill our evolving desires for ourselves, our children, and the planet.

Human experience is deeply rooted in food and in the cycle of human activity that includes food production, distribution, manufacturing, shopping, and finally, eating. This cycle shapes our daily lives at work and at rest, in politics and in play, in our bodies and in our imaginations.

For many of us, these food experiences are professional as well as personal. Food scientists and farmers alike experiment with ways to produce more, and hopefully higher quality, food. Entrepreneurs and innovators engineer processes to manufacture a cornucopia of flavors from a few staple ingredients. They design distribution systems that bring diversity to our markets, kitchens, and tables. They create shopping experiences that speak to our personal desires and foretell pleasures to come. And as mealtime approaches, they help busy humans, including themselves, make those pleasures both convenient and real in ways that range from healthy to hedonistic.

Over the last few decades, our planet’s complex food system has thus developed several core strategies for optimizing this cycle of food experiences. Production aims for intensification. Distribution requires efficiency. Manufacturing is at its best when it can be standardized. Shopping centralizes food in a common marketplace. And when it comes to eating, convenience and affordability still dominate diners’ considerations.

These strategies have been well honed by generations of people engaged in the experience of food. But today, these strategies are encountering their limits. Technological innovations are poised to take us beyond those limits, to transform the way we experience food in all our encounters with it. Over the next decade, we will re-experience food as we look to these technologies—not just to help us breach these limits, not only produce the food we need, but also to fulfill our evolving desires for ourselves, our children, and the planet.Explore 5 FOOD EXPERIENCES and their CORE STRATEGIES that are encountering limits:

For decades, speed and ease have defined eating: fast food, ready meals, and ?on-the-go? products. But the OECD has found that as we spend less time preparing our food, we?re packing on pounds. Mindless eating is driving lifestyle diseases among the affluent, while billions of others go hungry.

To address this dilemma, we will need to redefine convenience from being about getting food fast to making mindful and healthful eating accessible for all.

At-home Meals Decline

According to the USDA Economic Research Service, food expenditures for at-home meals by families and individuals have dwindled since 1900 as expenditures for food away from home have grown; the recessionary return to home cooking is a blip in a much longer trend.

Source: USDA Economic Research Service

Food Preparation and Obesity

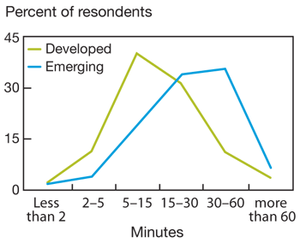

A Euromonitor International survey found most respondents in developed markets, where lunch is often eaten on the go, spend only 5-15 minutes preparing lunch; in emerging markets, respondents were three times more likely to spend 30-60 minutes preparing lunch.

Source: Euromonitor International

As the appliances in our kitchens, from refrigerators and stoves to pots, pans, cutting boards, and spatulas, gain the ability to communicate with us and with each other,cooking fresh meals will become increasingly easy and convenient, drastically reducing purchases of processed or pre-cooked meals. Kitchen helper tutorials and games will interface with numerous appliances and brands. Chefs and video game companies, food companies, grocery stores, and everyday people will create programs to promote cooking skills.

UC Berkeley researchers have experimented with using the Microsoft Kinect device in a kitchen environment to help people learn to cook with individualized, real-time feedback based on movement.

The Smart Manager system for LG?s refrigerator recommends meals based on the foods inside, and can even coordinate with other appliances, like the oven.

Source: LG

Technologies have become the nemesis of a mindful eating experience. But in the next decade, instead of just being a distraction, technology will be put to use to encourage eating mindfully. Visual, tactile, and other sensory feedback will reinforce positive habits, such as actively paying attention to food, body cues, and social company. The benefits of these practices will continue to be quantified and successfully deployed to prevent weight gain and to make eating experiences more social and enjoyable.

The HAPIfork electronic fork monitors your eating habits and alerts you with lights and gentle vibrations when you are eating too fast.

Source: hapilabs.com

In Amsterdam, Kit Kat?s ?No WiFi benches? disrupt all wireless signals within five meters, allowing people to focus on eating and being present with friends.

Source: psfk.com

People trying to lose weight have one obstacle above everything else: their own biology. Humans are hardwired to find sugary, fatty, calorie-rich foods delicious. However, in the next decade, new kinds of permanent surgeries will arise to change how our brains process taste and hunger; in other words, a gastric bypass for the brain. While today's food landscape is built around natural food preferences, the ability to effectively hack our brains could result in massive shifts in the quantity and types of foods we consume.

Rob Rhinehart, a 24-year-old man from Atlanta, GA, has found a way to live ?without food? by exclusively consuming an odorless beige drink called Soylent that contains every nutrient required by the body to function. In October 2013 he received $1.5M in VC funding to mass produce the mix.

Source: Soylent

Image Source: vice.com

Ghost Food is an experiment by artists Miriam Simun and Miriam Songster that uses scent to give people the illusion they are eating a different food than what they are actually consuming.

Source: Miriam Simun and Miriam Songster

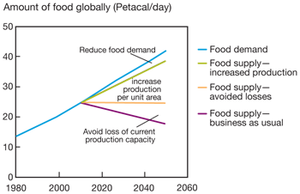

Over the past 50 years we've gotten more out of less: increasing yields, intensifying aquaculture, factory farms. But in the 50 years to come, this path will widen the gap between what we need and what we can produce. Degraded land, collapsing fisheries, and carbon-intensive production are problems that need action now to close the gap.

Technologies, and an ecological understanding of how to use them, will reorganize how and where we focus our quest for abundance.

Crop Intensification Rises

Indicators of crop intensification have risen steadily in past fifty years, while fertilizer use has skyrocketed.

Source: FAO 2011

Reconciling Intensification and Climate Change

The Commission on Sustainable Agriculture and Climate Change has identified three keys to meeting future food needs: production must intensify, loss through food waste and land degradation must decrease, and demand must be reduced through more sustainable global diets.

Source: ccafs.cgiar.org

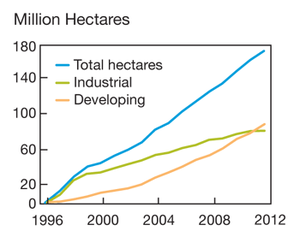

Rapid Growth in Biotech Crops

World annual production of cereals has nearly tripled over the past half century and fertilizer consumption is skyrocketing. Projected population and income growth, as well as urbanization, in many parts of the world point to even greater crop intensification in the next decade.

Source: actionforag.org

Communities' increasing demands for sovereign food systems will drive a shift from monocropping rural land to ubiquitous microfarming. Advances in film farming, aeroponics, and aquaponics will allow urban communities to grow food crops with minimal soil and water use, indoors and outdoors. Urban farming will transform from scattered rooftop gardens into dense local production, ranging from state-of-the-art vertical farms to derelict warehouses. Swarming robots and other autonomous machines enable cultivation on hard-to-reach surfaces in cities, and on depopulated rural farms.

Dubai-based Agricel enables no-soil low-water growing in indoor and outdoor conditions.

Source: www.agricel.co

Intensifying production not only on rooftops but also in legacy infrastructure demonstrates that local production can scale.

Source: farmedhere.com

Prospero is a working prototype autonomous robot that uses swarm and game theory to automate complex agricultural tasks.

Source: dorhoutrd.com

Substitutes and in-vitro creations are transforming animal husbandry. While biologists have begun exploring the use of stem cell technologies to create "in-vitro" meat, synthetics made from soy beans and other plants that are virtually indistinguishable from animal proteins are already hitting store shelves. Often cheaper and easier on the earth, these substitutes have the potential to reinvent protein. We'll see a shift from concentrated animal raising to synthetic substitutions. However, the opinions of consumers about these options will prove volatile as well.

Beyond Meat?s faux chicken is nearly indistinguishable from the real thing, even fooling New York Times critic Mark Bittman.

Source: nytimes.com

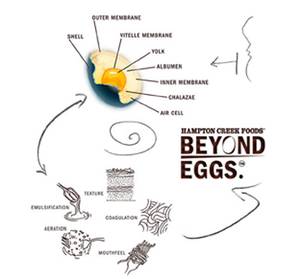

Hampton Creek Foods? Beyond Eggs, a cheaper, more sustainable, and healthier plant-based egg substitute is now available for sale at Whole Foods, and has been used as a replacement in industrial scale baking and mayonnaise production.

Source: hamptoncreekfoods.com

While today agriculture is the eighth-largest contributor to greenhouse gasses, it could quickly become one of the most powerful tools for mitigating climate change. Technologies and techniques are emerging to provide scalable solutions to thorny problems of waste management, soil depletion, and desertification. Re:char's model of selling the tools necessary to make profitable and ecological agricultural input exemplifies locally-appropriate replication of key technologies, combined with global knowledge-sharing and coordination.

Systems like re:char, which makes kilns that convert waste into a carbon-negative soil amendment that helps farmers grow up to 144% more food while sequestering carbon, illustrate farming methods that improve the environment, instead of minimizing damage.

Source: re-char.com

According to Allan Savory, rather than segregating livestock and wilderness preservation, combining them could reverse desertification and improve livelihoods across vast areas of the earth?s surface, making livestock key to reversing climate change.

Source: ted.com

Image source: Flickr Creative Commons User CIAT International Center for Tropical Agriculture

The past decades saw the rise of one-stop shopping. Supermarkets and big box retailers turned food shopping into a once-a-week activity where everything was offered in one place. This behavior is reaching its limits. Food waste plagues retailers and consumers want the real-time convenience of the Internet in the physical world.

Shopping will no longer be an episodic event, but rather something that can be done anytime, anywhere.

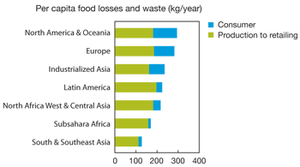

Waste-intensive Retail Models

Source: FAO 2009

Over the next decade, conventional food retail channels will be disrupted by a variety of new services promising on-demand home delivery. Offerings like Tesco's virtual grocery store in a South Korean subway, as well as more recent efforts like Starbucks? car dashboard that enables coffee ordering while driving, point to a retail future where food purchasing is independent of purchase location.These technologies will converge with systems such as Kiva Systems' automated warehousing robots and self-driving cars to create just-in-time home delivery services.

Chinese online grocery retailer YiHaoDian has created one thousand virtual supermarkets in vacant lots where shoppers can ?browse the aisles? and purchase foods for delivery with an augmented reality app.

Source: fastcoexist.com

Matternet aims to leapfrog road infrastructure in developing countries by using drones to offer more convenient and precise just-in-time delivery.

Source: huffingtonpost.com

As our refrigerators, cabinets, packages, and even bodies become connected in a tapestry of networked matter, shopping turns into a wholly automated process that requires no human decision-making. Food orders are determined by our inferred preferences and health needs and are triggered automatically when supplies dwindle. In this landscape, shoppers cease to consciously look for new options, rendering packaging and other aspects of persuasion irrelevant.

Rosie is a mobile shopping platform that learns users? purchasing behavior for home goods and food and anticipates when it should order more.

Source: rosieapp.com

The Amazon trash can is an MIT Media Lab concept product that scans items as you throw them away and enables you to automatically reorder them.

Source: David Rose

Consistency of taste and texture was a 20th century breakthrough. From Kraft's homogenized cheese to Coke's algorithmic orange juice, we have standardized even the most unruly ingredients. But this has meant selecting and processing?and some question whether the results are truly 'food.'

As commodity economics squeeze suppliers and consumers become skeptical of foods filled with sugar, corn, and additives, we?ll remix standardization. Processing will become transparent.

Manufacturing for Consistent Taste

Coca-Cola?s Simply Orange juice is manufactured using an algorithm to analyze 'up to 1 quintillion decision variables,' highlighting the increasing role of data in formulating and manufacturing food products.

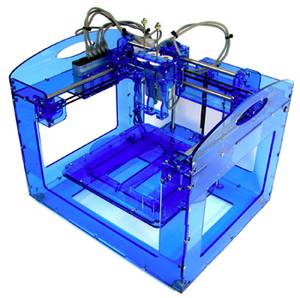

As improvements in small-scale electronics continue over the next decade, an increasing number of food manufacturing tasks that previously required large-scale factories and equipment will move to supermarkets and, at times, even into homes. Already,direct-to-consumer devices such as Soda Stream are enabling people to create soda in-home, while prototypes of 3D food printers point toward a future where local ingredients processed by lightweight equipment will disrupt large-scale manufacturing processes with locally customizable foods.

A Cornell University team has created a 3D printer that can fit in a consumer kitchen that replicates the taste and texture of bananas, mushrooms, and mozzarella.

Source: Cornell University

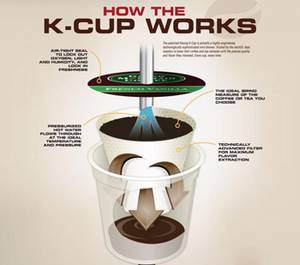

The K-Cup machine is a consumer device that precision brews a single cup of coffee, tea, hot chocolate, or other hot beverage with minimal effort from the user.

Source: Keurig

Technology has already greatly reduced the cost of producing many foods due to vast economies of scale. In the next decade, advances in digital manufacturing, sustainable energy, citizen-led bioengineering, and automation could reach a tipping point. The convergence of these technologies could make even very sophisticated food processing systems accessible around the world, reducing the set up cost of such systems to the point where communities could create self sustaining food commons that rival the technical sophistication of large-scale multinationals.

The Global Village Construction Set, from Open Source Ecology, is an open technological platform that allows for ?fabrication of the 50 different industrial machines that it takes to build a small civilization with modern comforts.?

Source: Open Source Ecology

Momentum Machines aims to open the first restaurant chain that sells gourmet burgers at fast food prices by replacing human cooks with their alpha machine.

Source: Momentum Machines

The shipping container transformed efficiency: flexible units stack together the power of ships, trains, and trucks. Efficiency rules for food headed to factories, restaurant kitchens, and markets. But we've made tradeoffs. Foods are not as tasty and nutritious as they once were. Some operations struggle to reconnect to local sources, while others must scale up—and efficient systems are often inflexible and brittle.

We will see a rebalancing towards resilience, local sources, and deliciousness.

Year-round Produce Availability

On average, food travels 1,500 miles from farm to plate. This distribution system feeds year-round demand for regionally out-of-season produce.

Source: Leopold Center for Sustainable Agriculture

Understanding food waste

As more countries industrialize, access to better post harvest infrastructure and technology will reduce waste in the distribution portion of the supply chain and push it towards the retail and consumption end.

Source: fao.org

Sensors to Reduce Food Waste

Researchers at Eindehoven University of Technology are developing packaging that could 'test' whether the contents are still safe to eat, which could greatly reduce food wasted because of confusion caused by 'best before' dates. The electric sensor circuits will cost less than one euro cent each.

Source: tue.nl

Today's distribution networks can quickly reach remote areas, but are dominated by large producers. Social technology platforms are poised to disrupt this system by allowing small-scale producers to piggyback on existing shipping, trucking, and rail infrastructure. This cuts out middlemen, automates administrative tasks, and provides logistical support to enable dynamic economies of scale. Seamless integration of small producers will allow procurers to meet demands for locally sourced food and reduced-waste.

Local Food Systems, Inc., allows small suppliers to sell to large procurers by using business-to-business technology to aggregate products.

Source: localfoodsystems.com

ColaLife is a non-profit that delivers essential medicine and nutritional supplements to remote regions by leveraging unused capacity in Coca Cola?s supply chains.

Source: colalife.org

United States Northwest-based FoodHub partnered with Massachusetts-based FoodEx to expand alternative distribution systems for local and regional producers.

Source: guardian.co.uk

An emphasis on efficiency and the deep integration of hackable technology leave food systems vulnerable to intentional disruptions. Additionally, the incredibly complex global supply chain for much of the world's food has proven itself difficult to monitor effectively. While profiteering and negligence provides a sufficient threat already, intentional sabotage of the food supply could cause significant illness and casualties on a near global scale, as well as mass panic.

A hacker hired by a large Southern California water system to test the vulnerabilities of its computer networks, was able seized control of the equipment that added chemical treatments to drinking water in one day.

Source: articles.latimes.com

In 2011, the FDA inspected just 6% of domestic food producers and 0.4% of importers, according to Bloomberg. Under the Food Safety Modernization Act there are still no requirements for microbiological testing to confirm the efficacy of safety programs.

Source: bloomberg.com

Image source: Flickr user The U.S. Food & Drug Administration

Acknowledging the danger of the ?financialization? of food, Barclays, Cr?dit Agricole, and BNP Paribas have agreed to close agricultural commodity speculation funds. According to Oxfam, in the past five years financial speculation on food has nearly doubled from US $65 to $126 billion annually.

Source: oxfam.org

Image source: Flickr user heatingoil

How to use the SEEDS OF DISRUPTION map

PRODUCTION

DISTRIBUTION

MANUFACTURING

SHOPPING

EATING

DISRUPTIONS and WILDCARDS provide a more detailed perspective on how our experience may change.

DISRUPTIONS and WILDCARDS provide a more detailed perspective on how our experience may change.

SIGNALS show examples of how these possible futures are already starting to manifest today.

SEEDS OF DISRUPTION

HOW TECHNOLOGY IS REMAKING THE FUTURE OF FOODFOOD EXPERIENCE: EATING

REDEFINING CONVENIENCE: from on-the-go eating to mindful food experiencesDISRUPTION: Leveling-up cooking skills

SIGNAL: Perfecting technique with 3D cameras

SIGNAL: Networking smart appliances

DISRUPTION: Augmenting mindful eating

SIGNAL: Quantifying eating speed

SIGNAL: Forcing digital sabbaths for uninterruped snacking

STRAIN OF UNCERTAINTY: Taste rewired

SIGNAL: Bypassing the need for real food

SIGNAL: Deceiving the brain

FOOD EXPERIENCE: PRODUCTION

REORGANIZING INTENSIFICATION: from resource-intensive agriculture to low-impact alternativesDISRUPTION: Growing food on every surface

SIGNAL: Growing crops without water or soil

SIGNAL: Repurposing abandoned urban space

SIGNAL: Swarming robot farmhands

DISRUPTION: Transforming protein

SIGNAL: Fooling food critics

SIGNAL: Reformulating eggs

STRAIN OF UNCERTAINTY: Climate-resilient agriculture

SIGNAL: Replicating carbon negative farming

SIGNAL: Grazing to reverse desertification

FOOD EXPERIENCE: SHOPPING

RETHINKING CENTRALIZATION: from centralized shopping sites to just-in-time deliveryDISRUPTION: Grocery shopping without the store

SIGNAL: Augmenting vacant space

SIGNAL: Delivery by drone

STRAIN OF UNCERTAINTY: Decision-free shopping

SIGNAL: Anticipating purchasing needs

SIGNAL: Automating purchases

FOOD EXPERIENCE: MANUFACTURING

REMIXING STANDARDIZATION: from standardized to personalized formulationDISRUPTION: Taking manufacturing local

SIGNAL: Hacking texture

SIGNAL: Automating precision coffee making

STRAIN OF UNCERTAINTY: Open food manufacturing commons

SIGNAL: Constructing industrial machines

SIGNAL: Replacing line cooks

FOOD EXPERIENCE: DISTRIBUTION

REBALANCING EFFICIENCY: from large-scale efficiency models to distributed resilienceDISRUPTION: Tapping distribution networks

SIGNAL: Aggregating B2B demand

SIGNAL: Filling supply chain gaps

SIGNAL: Sourcing local

STRAIN OF UNCERTAINTY: Supply chain sabatoge

SIGNAL: Hackable infrastructure

SIGNAL: Exposing inspection gaps

SIGNAL: Speculating no more