Future Now

The IFTF Blog

MakerBot Day 2: I Start to Build

Let me start off by saying that I mean this in the nicest way possible -- I am really enjoying the lurching process of building my MakerBot, and am more than happy to get the chance to work my way through the assembly of the machine.

That said, if the MakerBot is the future, then the future is f*&@ing complicated.

Yesterday I overcame my fear of the unknown and broke into the Thing-O-Matic (TOM) packaging, and what I found was as daunting as I had anticipated. In clown car fashion, lasercut pieces, electronic components, motors, cable, and the awesomely named Thing-O-Matic Hardware Burrito were transferred to my kitchen table-cum-workshop.

My kit, artfully arranged on my kitchen table.

The TOM does not ship with any instructions, but rather maintains a mostly-comprehensive (I'll talk about this in later posts) and continuously updating online user manual that incorporates the latest innovations and tweaks to the process that MakerBot and the TOM community have identified. After breezing though the "Before You Begin" section, which consisted of the kind of pre-flight checks that in hindsight I shouldn't have breezed through, I made my way to the first step in the Build Process: X Stage Assembly.

What was in the Thing-O-Matic box. (Image c/o MakerBot Flickr stream)

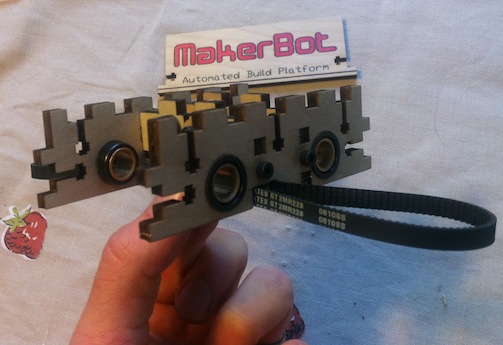

I was immediately faced with the fork in the road, as I had to choose a build platform - the surface onto which the superheated ABS (Acrylonitrile butadiene styrene, a thermoplastic that "possesses outstanding impact strength and high mechanical strength, which makes it so suitable for tough consumer products." Thanks, Dynalab Corp!) will be applied. Brimming with optimism and confidence in my ability, I opted for the Automated Build Platform, the most complicated of the choices provided. Because, as I learned in college, go big or go home.

I realize I am betraying the degree to which I am not a tinkerer, but I immediately regretted my choice. What was billed as an Estimated Build Time of approximately 1 hour took my Dad (who coincidentally is visiting and has been drafted into service of the Future) and me almost half a day.

How was this possible? Granted, I'm not TechShop-instructor familiar with putting things together, but at the same time I think I am pretty good at these kinds of things. Moreover, my Dad is a Professor of Civil Engineering - a veritable heavyweight when compared to my liberal arts-degree pedigree.

My initial sense is that the immense frustration I felt while I put together the machine has less to do with the actual machine itself (yes, the need to constantly check and re-check the lengths of different bolts is tedious at its best, but I can't fault Makerbot for the fact that nuts and bolts are the most sophisticated fastening technology that humans have come up with thus far).

Base for Automated Build Platform (X-stage/ABP)

Rather, I think that a lot of the hurdles I am encountering and eventually overcoming have to do with my internal tolerance for deviating from the instruction manual. Owners of the early generations of 3-D printers are obviously a fairly niche group of the Maker community, and given their familiarity with many of the constitutive parts of a TOM, they are likely less reluctant to fly by the seat of their pants when directions and reality diverge.

As it stands, however, being of a mindset of, "not wanting to screw up a $1000 machine", there have been a lot of moments where the disjuncture between what I see in reality and what is shown online was both puzzling, and cause for heated discussions with my dad.

A lot of these gripes are over little things: I have no way of knowing if the friction between the belt and the screws will cause my machine to explode, or if the millimeter of uncovered heat board will make my house burn down.

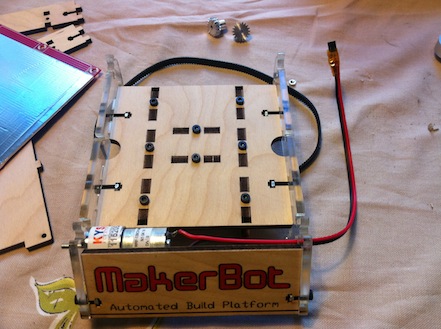

In progress ABP with dreaded heated platform visible to the side

More fundamentally I think that it comes down to not knowing how the various components ultimately function within the to-be-completed TOM. Without a sense of which parts have the potential to turn IFTF's investment into a fiery heap of paperweight. Which means that I treat each bolt, nut, and piece of laser-cut wood as delicately as a Fabergé egg, instead of the rugged piece of super-heated-plastic spewing robot that it is.

In this sense, a large part of these early stages of putting together the Thing-o-Matic is learning which instructions are loose guidelines, and which are must-follows. This type of contextual awareness is something I will likely (hopefully) develop as I get deeper into the weeds, and what better way to learn than to re-launch myself into the next part of the TOM build process: the Y-Stage Assembly.

Completed ABP