Future Now

The IFTF Blog

Maker Cities: Shenzhen

A research team from the Institute for the Future recently visited Shenzhen to explore the maker culture of the city. We toured factories and experienced the city’s first official Maker Faire. The Faire was full of groundbreaking maker technologies that we were seeing for the first time in Shenzhen. An Open Source Vehicle with the potential to transform traditional transportation systems. An enormous variety of electronic components, available for preorder and ready to help you prototype any connected device imaginable. Dozens of 3D printers are available to give those imagined devices a physical form. Little kids flying quadcopters through brainwaves and a dancing robot made of FDM components. Makers had traveled thousands of miles from all over the world to be there.

When compared with the much larger Bay Area Maker Faire, Shenzhen’s Faire felt just slightly more like a trade show. This wasn’t surprising given the region’s vast networks of OEMs and rich manufacturing supply chain. But the objects on display shared a common set of maker movement values. In fact, one of the most surprising things about visiting China was seeing the universal core values of maker culture in action. Those values have been expressed in many different manifestos (see: Maker Movement Manifesto, Self Repair Manifesto, Making Manifesto Africa, Maker’s Bill of Rights, Fixer’s Manifesto: Education Version, etc.) These values essentially boil down to this:

publish openly

experiment, fail, try again

collaborate and share what you know

make things that can be hacked and remixed

have fun with your fellow maker

These maker values are changing how people interact with their environment. As I’ve written about before, if we were to see these values widely adopted by everyone, then we would have the power to radically transform any city.

Making in China isnt a new story though. China is the world’s largest supplier of electronics manufacturing services, and the Pearl River Delta has spent decades tooling up as a traditional manufacturing powerhouse; Guangdong’s economy is the largest in China, surpassing $1 trillion in 2013. More recently, with the advent of the Maker Movement, we are starting to see the regions like Shenzhen grow from the bottom-up. Driven by government efforts, grassroots maker partnerships, and stronger connections to funding streams, cities like Shenzhen are becoming recognized as all-around global innovation centers.

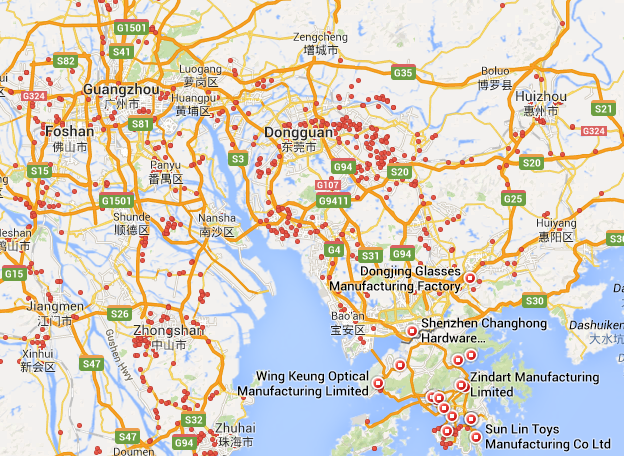

This map of chinese manufacturers is a googe map search for "Shenzhen, manufacturing" from Eric Pan's presentation at Maker Faire.

The very idea of what it means to be innovative is changing. Innovation used to require scale— a million units of the next must-have gadget. Successful innovation meant being acquired for an astronomical sum of money. Smaller-scale Maker-led innovation took time for Chinese manufacturers to adapt.

An illustrative example is the Pebble smart watch. It was a breakout success with a crowd-funding campaign that raised over $10 million USD, selling 85,000 units, and surpassing their goal by a factor of 100. Crowdfunding success stories to bring electronics devices to the mainstream were previously unheard of. It figures that there was no need for a robust small scale manufacturing capacity, and when confronted with the opportunity to manufacture Pebble watches, many of the larger electronic manufacturers were totally unprepared. Hardware incubators and accelerators such as Dragon Innovation sprang up to fill this niche in the ecosystem, helping growing companies such as Pebble plug into manufacturing and distribution chains of China. In 2013 the manufacturing giants weren’t yet ready to work with Pebble, but they did see an opportunity for innovation.

During the Maker Faire, two people took the stage to discuss innovation and manufacturing in China. Foxconn’s Vice Chairman Vincent Wang, and Eric Pan, the founder of Seeed Studio. Seeed Studio came from Maker roots, they are an electronics manufacturer framed as a Maker business, and growing fast. Foxconn is a global manufacturing powerhouse. On this panel, Wang discussed InnoConn, a new special business unit and fabrication facility at Foxconn. This new unit is tasked with streamlining the logistics of small scale manufacturing, and preparing to work with different types of innovators, something on the scale of Pebble or even smaller.

While Foxconn is beginning to ponder small scale manufacturing, Seeed Studio is already at the heart of the maker movement. Eric Pan has become a community leader, helping the local maker culture grow and organizing events such as the Maker Faire. Seeed sponsored the first Shenzhen hackerspace, ChaiHuo, where potentially anyone can learn maker skills. When the IFTF team was on the ground in Shenzhen, we were fortunate enough to visit ChaiHuo where we met several local makers who were prototyping exercise products and open source robotics kits. Seeed Studio’s strategy for community development is directly in line with the global maker ethos, and it is going far beyond the notion of what a traditional electronics manufacturing plant looks like.

As we see manufacturing in China open up to a wider audience, it is becoming a global center for local innovation. While this new manufacturing ecosystem is changing the landscape of innovation in China, it is transforming the world. Through embracing the Maker ethos, a city like Shenzhen opens up opportunities for not only manufacturing, but also designing and prototyping innovative new products and systems for a market place with unlimited possibility.

This post is part of a series related to IFTF's Maker Cities, an early prototype of an online multimedia conversation platform for global makers. Our Technology Horizons program developed this lightweight crowdsourcing site to ask the public, “How will your city be a Maker City in 2025?” Built with repurposed open-source software from Ushahidi originally designed for post-disaster mapping, Maker Cities is the first such platform to quickly capture makers’ on-the-ground signals and future visions for more participatory Maker Cities. Now is your chance to play the game! Contact Alex Goldman (agoldman@iftf.org) for more information.