Future Now

The IFTF Blog

Make It Just So

A look at the coming world of anticipatory retail

Written by IFTF Research Affiliate Scott Minneman for volume three of Future Now,

IFTF's print magazine powered by our Future 50 Partnership.

Clea and her 8-year-old son Alex are in a coffee shop before school. It’s Alex’s birthday. While waiting for their latte and hot chocolate, they play with a tabletop social robot that the coffee shop has to amuse customers. Alex is charmed by the robot’s engaging antics, and Clea, (who still hasn’t found the perfect gift for her son yet), wants to give him one like it for his birthday. She snaps a few photos of the robot, and an anticipatory software agent on her phone asks her if she’d like to purchase one. It’s $800, which will bust her budget. But an assortment of other options are offered, ranging in functionality from clunky plastic statuettes to fully motorized articulated robots, some with only crude sound effects, to others with full interactive speech capability. Clea notes a brand she bought for Alex’s older brother a couple of years back and chooses it, along with the all-important joke-library subscription. The price is right, coming in at a quarter of the price tag for the larger more elaborate coffee shop robot. She selects an Iron Man skin that she knows Alex will like, and selects a delivery time when Alex is home from school.

Clea’s order is routed to a “fab shop” across town. It’s a one-person operation owned by a guy named Ron. He notes the various modules needed for the desired features, and lets the design software chew on the photos Clea took, creating the functional layout and surfacing to match the coffee shop bot. A quick check-in with Marvel gets the Iron Man finish applied, and Ron hits the “make” button. As the parts emerge from the machine, he snaps them together around a few Tamiya motion, Qualcomm speech, and Panasonic battery modules. It goes together without a hitch, and Alex is delighted when a delivery drone buzzes into his front yard and drops his new birthday toy into his hands!

Mass Customization Is Bringing People Back Into the Picture

Modern manufacturing strategy can be reduced to a meme: “Make things right. Make the right things.” But mass production merely “satisfies” customers, giving them inexpensive, well-made goods that don’t fully serve their needs and desires. Clothes are ill-fitting, features are missing, flavors are bland and tailored for consumers that fall within one standard deviation around the median.

Modern manufacturing strategy can be reduced to a meme: “Make things right. Make the right things.” But mass production merely “satisfies” customers, giving them inexpensive, well-made goods that don’t fully serve their needs and desires. Clothes are ill-fitting, features are missing, flavors are bland and tailored for consumers that fall within one standard deviation around the median.

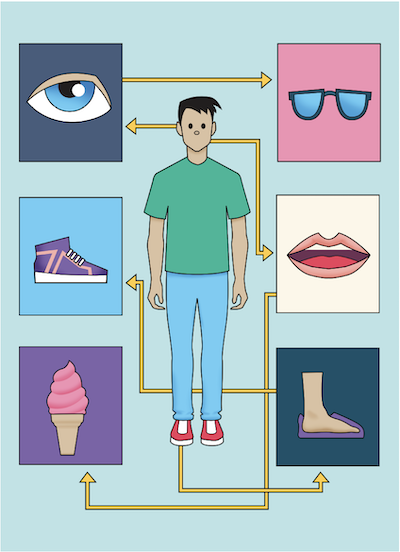

But the days of suboptimal, nearly identical items are numbered. Over the next decade, traditional mass production will be replaced by forms of automated manufacturing in which objects are customized to individuals’ particular circumstances and desires, without the high costs and slow turnaround that’s always been part of bespoke production. Automated manufacturing has been making inroads in the manufacturing sector for decades now. Pick-and-place robots in electronics assembly, cleanroom robots in biology laboratories, and, of course, the massive assembly-line robots of automobile production are commonplace. Automation displaced many assembly worker jobs, but product complexity and demands for quality demanded this transition. Looking forward, the pace of automated manufacturing will accelerate and morph as sophisticated functional modeling, advanced fabrication methods, and novel forms of robotics colonize new territory for automation.

Manufacturing will undergo further changes as time-to-market becomes an increasingly critical factor in a product’s success, as certain capabilities, once available to only the largest companies work their way down to smaller companies and individuals, and as the era of single-product offerings for large swaths of the population continues to wane. Ramping up production of a new product, making small batches to meet demand, and just-in-time production require agile automated manufacturing methods that can switch tasks frequently and acquire new production capabilities on demand.

We will see advances in the following areas:

- Robots that learn from watching something being assembled or repaired

- Products that are autonomously assembled on a per-consumer basis from kits and subassemblies (think IKEA, but with a delivery/assembly system that shows up in your living room or study)

- Core functionality aggregated and modularized to support expanding degrees of customer-specificity

- Cobots—robots designed to work with and alongside humans—that produce flexible and customized manufacturing outcomes while minimizing lengthy development time for workcell engineering and robot programming

Autonomy in manufacturing manifests in broader terms, too. Supply chains, transportation, packaging, distribution, and delivery are becoming increasingly automated. Self-driving vehicles, drone delivery, mobile factories, and supply-chain automation will merge with end-to-end manufacturing lines and artificially intelligent production logistics, with the result that final assembly will migrate into fulfillment centers for custom just-in-time production after an order is placed.

Disrupting Large-scale Organizational Advantage

Emerging automation technologies are lowering barriers to participation in the manufacturing sector. Large companies still have an advantage in some markets, and monster-size companies for raw materials and many core-components products aren’t going away—there’s simply too much capital investment in state-of-the-art factories for that to happen. Still, agile entrepreneurs are eroding some of that advantage, seeing gaps in the offerings of the giants and stepping in to fill those gaps. Especially during development, complex designs can be simulated in software, prototyping of highly-sophisticated parts and assemblies can be done in-house (sometimes literally, from a kitchen table), with iterations happening overnight. Crowdfunded development, cottage industries, and an increasingly globalized pool of capacity is radically altering how and where various parts of production occur. Individuals and small teams can band together in virtual workplaces, novel objects can be designed, modeled, and tested in advanced CAD software, prototyped and further verified using myriad rapid-prototyping resources (including automated bill-of-materials generators/sourcers), assembled and tested in moderate runs all over the globe, and fulfillment centers are poised for packaging and distribution.

Rapid Protoyping Becomes Rapid Manufacturing

Breakthroughs in 3D printing are also shifting the autonomous manufacturing terrain. New materials and processes will emerge to push increasingly-versatile capabilities into more sectors: multi-material printing, with metals (structural), conductors (internal wiring), flexibility (aesthetics and comfort), and geometries (function), coupled with robotic jigging, integrated subtractive processes, and parts inclusion (e.g., electronic chips, connectors, fasteners, or bearings included in the material matrix). Applied and integrated images and patterns will allow mass customization for a vast assortment of products. Instrumented products and expanded computational modeling will support continuous improvement of products, allowing for during-run changes to address failures and improve performance.

Knock-offs and Lock-downs

These advanced capabilities will also create intellectual property wars. The ease of superficially copying and reverse-engineering products will fuel counterfeiting efforts. Manufacturers will respond by making products that are difficult to knock off. They do this by using included-component fabrication methods, (which makes it difficult to reverse engineer the hardware), embedded and encrypted functionality (making the underlying software impenetrable and/ or inscrutable), and subscription-based value (authentication). These counter-counterfeiting efforts will increase tensions with portions of the consumer base that desire serviceable and stand-alone products, and consumer-rights litigation and regulation will arise at national and international scales.

Fadufacturing

Figuring out what to make will, at least on some simple levels, be subject to automation. Fads and fashion are notoriously difficult to predict, but they are easy to exploit. Being first to a market is great. Not far behind, is getting there soon after with a knock-off. In the age of social media, tracking trends is easy, and autonomous manufacturing makes getting lined up to capitalize on trends cheap. At the lowest end, getting out there with “Covfefe” t-shirts and coffee mugs wouldn’t require a rocket-scientist. One would watch for trending stuff on Twitter, snapping up domain names, buying appropriate Google AdWords, harvesting some tweets for good quotes, authoring a simple e-commerce site. Moving up one level, artificial intelligence (AI) driven manufacturing can rapidly be put to use to make accessories for newly-released products (e.g., today’s phone cases, tomorrow’s augmented reality (AR) frames) and counterfeiting fashion offerings. Exploding trends like fidget spinners, with added features like LEDs and Bluetooth speakers, and going upscale with advanced materials, are obvious places for short run, fast-turnaroud product offerings.

AI-enhanced Innovation

Expanding the terrain of design automation, AI will constantly be analyzing existing products for possible improvements in form and function. As new chipsets and sensors are introduced, automatic redesign will incorporate them to offer improved functionality and simplicity. Better sensors, longer-lasting batteries, and improved connectivity may be introduced into products without consumers having to wait for the next major product release. Today’s CAD packages incorporate amazing algorithms that generate optimized organic forms that could not be made without additive manufacturing. These visible and invisible tweaks can be folded into products during their runs.

At a very optimistic level, advances in autonomous manufacturing will help us figure out what’s actually worth making, and how best to do so. By incorporating big data, systems understanding, and functional modeling we can encode more nuanced value systems than “can money be made here?” into our choices. These evaluations will range all the way from what we make, to what we use for materials, to where things are made and to discoveries of how to make things with repurposed or recycled materials. Autonomous manufacturing that helps us “make the right things” may herald a new era of consumption that can better align our penchant for new things with our responsibility for the future of the planet.

FUTURE NOW—Reconfiguring Reality

FUTURE NOW—Reconfiguring Reality

This third volume of Future Now, IFTF's print magazine powered by our Future 50 Partnership, is a maker's guide to the Internet of Actions. Use this issue with its companion map and card game to anticipate possibilities, create opportunities, ward off challenges, and begin acting to reconfigure reality today.

About IFTF's Future 50 Partnership

Every successful strategy begins with an insight about the future and every organization needs the capacity to anticipate the future. The Future 50 is a side-by-side relationship with Institute for the Future: a partnership focused on strategic foresight on a ten-year time horizon. With 50 years of futures research in society, technology, health, the economy, and the environment, we have the perspectives, signals, and tools to make sense of the emerging future.

For More Information

For more information on IFTF's Future 50 Partnership and Tech Futures Lab, contact:

Sean Ness | sness@iftf.org | 650.233.9517